First let me give a huge shout-out to Aaron who helped me with questions, and examples, on how to get this out properly.

Seriously, thanks man!

This is not very difficult to do once you know what's what. Pay attention, take it easy, and you will get it out without issues.

There are many variations you can do to get the differential out but you can definitely get it done the way it is described in here (the steps are in a relatively logical, so if you're going to follow through do it in the order provided).

I removed mine with support member/crossmember. I think it easier, also you can inspect the condition of your bolts and bushings while you're at it. You can separate the diff from any supporting components later (or as needed).

1) Remove your exhaust starting from the axle to the rear muffler.

Or you can remove the whole exhaust system at whatever the next available service point is (i.e. catcon, or downpipe, header etc.).

If you need to cut your exhaust cut with enough room for the diff to come out without being obstructed.

2) Drain the Gear Oil and AYC fluid.

3) Remove rear struts/shocks completely. Unbolt the strut from the lower arm and remove the two bolts at the top of the strut tower (if you have a strut bar you may want to take that off too for easier dismounting).

Also if you loosen the bolt holding that lower arm to the crossmember it will be easier to get the strut out.

Unbolt the lower arm from the rear knuckle and push down on it so that it rotates on the (still attached) bolt on the crossmember, this should give you enough room to pull the strut downwards and out.

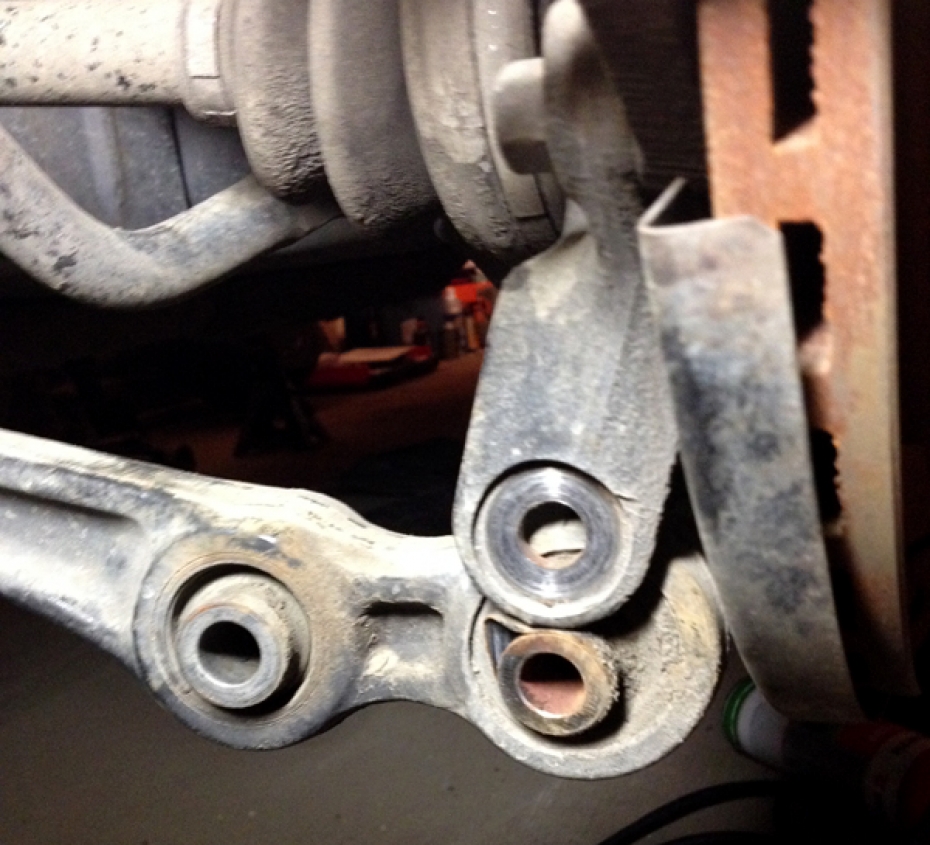

4) Unbolt the other arms to be able to rotate knuckle. Unbolt the lower arm (i.e. above picture), the toe control arm, and the trailing arm.

Toe control arm:

Trailing arm:

5) Remove the sway bar. Apparently I didn't take too many pictures of that but basically unbolt the end link from the knuckle and any other bolts holding the sway bar to the crossmember (you can leave the end links attached to the sway bar and wiggle it out).

6) Separate the axles from the wheel hub. (I left mine in to remove later, I wanted to drop the whole thing in one piece). You can use any kind of system you desire, punch them out, or use a specific puller, I used a claw type puller (this required me to remove the brake caliper, and the rotors, to wrap the tool around the hub).

7) Remove your AYC "stuff". Depending what you are doing you may not need to remove the whole AYC system (you can probably just disconnect your hydraulic lines and any bracket holding them to anything on the crossmember or elswhere). However for my purposes I removed everything and you can read about it in my "Evo IV AYC pump removal" blog.

8) Unbolt the drive-shaft. Be sure to support your drive-shaft with "something" so it doesn't just drop/cause any damage.

You can rotate your driveshaft by hand to get at the bolts (there should be 4 you need to unbolt), to stop the driveshaft from spinning put the car in gear. You will very likely have to have to wrenches on each side of the bolts so they don't spin (I found this to be a major pain in the ass with the limited amount of space I allowed myself underneath the car).

Then you just pull the bolts out and it will separate at that junction.

9) Support the diff and unbolt the support member/crossmember from the body and lower to it the ground. Go easy and take your time so you don't drop it, try to lower it as straight as possible so you don't damage any bolts.

Be careful with your bolts (some of them go into the uni-body). Try not to use power/impact tools or you may set yourself back a little by twisting or breaking bolts/threads.

10) Remove the axles or anything else you need to separate the diff from.

So far while removing the components from around the diff I have experience one major problem. The rear lower control arm camber bolts are NOT coming out.

The nut, washer, plate came out with no issue, however the bolt itself appears to be stuck in the bushing. It looks like next steps will be cutting the support frame and hopefully getting the bolt out of the bushing - if that doesn't come out the bushing might be garbage too.

Moving on past the above statement, I did end up cutting the support frame - with a hacksaw! It's super soft so it wasn't too much effort at all.

I also then managed to hammer out the seized camber bolts. And by hammer I mean full swing maximum force HAMMER with spraying of WD40 into the cavities many many times. I got them out without damaging the bushings so that's good.

I will not be updating this beyond this point since we are already getting off topic here so there is no need to continue.

|

|